Sheet metal processing

FlexInSheet Ltd. has a modern sheet metal processing machine park for the production of its own developed products, with which we are happy to undertake coil sheet metal processing, tableware production or complete sheet metal component production based on individual orders. We also help our partners with our 3D modeling software and our engineering capacity and experience. We have installed industrial robots for our bending machines, with which we can bend large series of sheet metal products continuously for up to 24 hours, almost without human intervention.

Robotised sheet metal bending for the mass production of sheet metal products

Our company strives for the most efficient work possible from the beginning and this can increasingly be guaranteed during the mass production of bent products by installing advanced industrial robots. The UR10e type ’cobot’ or collaborative robot of the Danish Universal Robots entered into service in the plant of FLINS in 2023, which serves a Finnish-made CoastOne servo bending machine. The application of this technology ensures an increased manufacturing precision, furthermore the production can be carried out without interruption up to 24 hours a day with its help. The robotic arm working together with our professionals efficiently and safely optimises our entire activity and ensures exceptional efficiency in the mass production of bent sheet metal products.

Sheet metal bending, sheet metal working

Our German-made ASCO Variobend DB 6.2,00 up and down bending machine with tilting table can produce almost any profiles up to a length of 6.40 metres. The elements can be extendable or have non-parallel edges too. The maximum sheet thickness is 2.00 mm (in the case of a material of a tensile strength of 400 N/mm2). The manufacturing speed and flexibility of the machine together with the advancement of the control software guarantee accuracy and short production deadlines. Furthermore, the current machinery of FLINS includes a Finnish-made CoastOne C9 and C15 bending machines. Both of them are characterised by high manufacturing speed and repeatability (+/- 0.002 mm), an extensive set of tools (making it possible to bend almost any profiles) and graphic bending simulation.

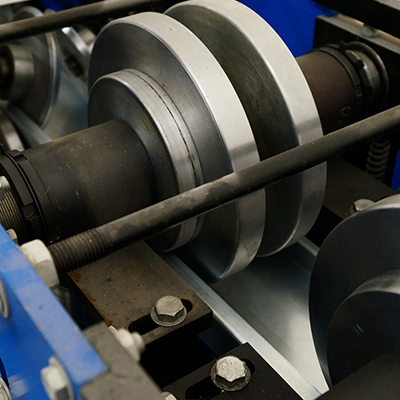

C-shaped ridgepole production

Our company has a significant experience in cold rolled steel forming, and thanks to this we produce C-shaped ridgepoles among other things by high productivity and accuracy. We can make high-quality products of up to 1860 running metres per shift in our machine shop on our uniquely designed and produced ridgepole rolling machine even in a unique design. In FLINS there is the possibility of producing ridgepoles with a cross section of C150 x 42 x 47 x 1.50 mm and the length is only limited by the size of the coil and the transport possibilities. The ends of the C-shaped ridgepoles having an excellent rigidity of shape and stiffness are formed with a hole pattern compatible with the ridgepole extension produced by our company.

Raw material: HX300LAD Z275 g/m2 + TOC

Laser cutting

In the case of a number of production tasks and challenges laser cutting can be the most efficient – and most economical – solution, hence this technology must definitely be included in the range of activities of FLINS. In our company a 1530 G-type, 3 kW fibre laser cutting machine made by LSL takes care of the high-quality fulfilment of such customer needs up to a sheet metal size of 1500×3000 mm. The maximum available material thickness is 15 mm in the case of carbon steel and 8 mm in the case of stainless steel. The laser cutting machine is capable of reaching up to 300 mm/s cutting speed in the case of thin sheet metals due to its precision servomotor and power. Thanks to the 0.01 mm cutting accuracy, fastness, quality and precision are also guaranteed.

CNC plasma cutting

We can use our high-precision plasma cutting machine bearing the name of the British ESPRIT ARROW company to cut special shaped sheet metal parts with a material thickness of less than 2.00 mm. The excellent cutting quality expected by the market is ensured by the American HYPERTHERM power source and the CNC control software among other things. Materials which can be processed with this technology include uncoated carbon steel, stainless sheet metal, galvanised steel sheet and aluminium. The maximum material thickness can be 10 mm in the case of carbon steel and 3 mm in the case of aluminium and stainless steel. The CNC plasma cutting service of FLINS ensuring an extremely competitive price and short delivery times is available up to a sheet metal size of 1500×3000 mm.

Production of unique and small series products

You cannot only count on the reliable work of FLINS team having considerable professional experience and knowledge in the case of orders for large series of products. Building on our modern machinery we undertake the complete production of unique products even consisting of several elements with complex geometry and special functions too. As one of the trademarks of our company, we always strive for an outstanding added value and complex solutions during our activity. Accordingly, we can already help with the professional design of the elements and the elaboration of the manufacturing technology in projects of unique and small series products. We contribute to the assembly of the elements made with high accuracy after the production on request.

Sheet metal cutting

We cut different materials up to a sheet size of 1000×2000 1500×3000 mm economically with the MTA 2060 x 3 NCC-type metal shear made by the Austrian Bernardo. The rear bumper of the machine with a 4 kW engine power can be adjusted automatically and quickly while the also automatic shearing function further increases the manufacturing speed in the case of large series. The metal shears in the own plant of FLINS make it possible to shear extremely precisely and burr-free, while you do not have to worry about the twist of the product either. The available maximum shearing length in our sheet metal cutting service is 2060 mm, while the maximum sheet thickness can be 3 mm in the case of carbon steel (tensile strength: 400 N/mm2).

Coil sheet metal processing

You can turn to FLINS team with various orders related to coil sheet metal processing. A TEH.1.25-type roll forming machine equipped with a CNC punching unit designed and produced by our company makes this easier for our qualified colleagues. The machine is suitable for the preparation of the raw material arriving in coils and the making of sheet metal panels necessary for further productions. Thanks to the above-mentioned special accessory they can be produced with unique hole patterns too. Our roll forming machine is capable of rolling coil sheet metal up to a width of 1250 mm and a material thickness of 2.00 mm, and making 4 cuts of 1 coil with its 3 shears.

Part design and optimisation

The most modern types of software are available in our company for the professional design of new parts and the modelling of their use. If we together with our customer consider it useful, we are ready to start the process with a thorough on-site survey. Our current service covers the production of parts based on a sample, or the optimisation, development and production of existing parts. With such ’improvements’ our customers can achieve a considerably increased efficiency, and they can also reduce their costs significantly in the long term, based on our experience. Our complex part designing and optimising service is characterised by the usual high quality and short deadlines.